Lean Lab: Successfully optimizing a laboratory with Lean

Lean is a management approach to improving processes that originated with the Japanese car manufacturer Toyota and became widely known as a result of a study conducted by the Massachusetts Institute of Technology (MIT) in 1991. The aim of lean management is to achieve performance with the lowest possible costs and the highest possible quality.

In order to achieve this goal, a large number of optimization techniques have been developed over the decades. Under the heading “Lean Lab”, these techniques have also been successfully applied in laboratories to a wide range of topics. These include, for example, laboratory processes, the design of the laboratory layout, but also documentation and management. Numerous studies have shown that impressive results can be achieved through the use of lean management.

Background

E-learning: Online course

Lean is translated as “lean” in German. However, lean means more than just “lean” in the sense of using resources sparingly. Lean management aims to optimally coordinate all activities that are necessary for value creation in order to avoid waste ( “muda” in Japanese ) and continuously improve processes.

The core idea is to create value for the customer without waste. In other words, lean is about consistently focusing on customer needs by reducing to what is of value to the customer. To achieve this, lean encompasses a bundle of approaches, principles (e.g. pull principle) and techniques (e.g. 5S). This is why it is also referred to as lean management – because it encompasses more than just a package of optimization techniques. In the laboratory, the term “LeanLab” is often used instead of “Lean Management”.

The history of Lean

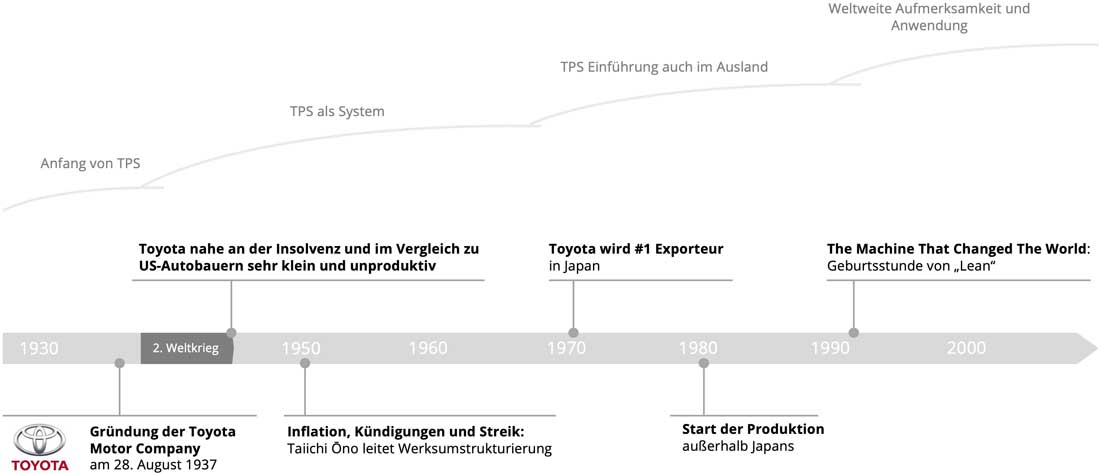

The foundations of "Lean" were developed by Toyota after the end of the Second World War.

The origins of lean management go back to the period after the Second World War, when the Japanese automotive industry was facing major challenges: a destroyed supplier industry, a shortage of resources (e.g. spare parts and capital) and strong competition from Western car manufacturers. To respond to these challenges, Toyota and Taiichi Ohno developed the so-called Toyota Production System (TPS), with the principles of just-in-time, kaizen and jidoka.

The effect of the Toyota production system was enormous: in the 1970s and 1980s, it helped Toyota to rise from a small and very unproductive manufacturer to become Japan’s largest exporter with strong competitive advantages. This is why it was also referred to as the “Japanese threat”.

To better understand this threat, a comprehensive study was conducted by the Massachusetts Institute of Technology (MIT). The results of the MIT study were published in the 1991 book “The Machine That Changed the World: The Story of Lean Production – Toyota’s Secret Weapon in the Global Car Wars That Is Now Revolutionizing World Industry” – the book became a bestseller. In the book, the term “lean” is used to describe the “Toyota Production System” and has helped to popularize lean management. Today, lean management is used in almost all industries worldwide and can be applied to almost all areas within a company. The principle, which was originally developed for the automotive industry, has evolved into a comprehensive management philosophy.

The 5 core principles of Lean

The following 5 principles form the core of Lean

1. focus on the customer

The focus is on the customer’s wishes and requirements. As the recipient of the goods or services, they can assess whether the right thing is being delivered in the right quality, in the right form and at the right time.

2. identification of the value stream

All work steps required to manufacture the product or service are identified. This allows hidden problems or waste to be identified.

3. reduce waste

Processes are designed in such a way that “inefficiencies” in processes are reduced, e.g. running, waiting, errors, complex processes without added value.

4. application of the pull principle

The starting point for the value creation of a product should be the customer’s order so that, ideally, no storage is necessary.

5. the continuous improvement process

A one-off optimization is not sufficient; processes must be continuously improved. This principle is also known as Kaizen.

The Lean method kit

More than 50 lean techniques can be found in the lean method kit or lean tool box.

The techniques can be divided into both techniques for analyzing improvement opportunities and techniques for improvement itself. Each of the tools enables certain improvements – for example, reducing costs, increasing quality and reducing lead times. Depending on which goals are to be achieved, the appropriate lean techniques must be selected. Selection is often the first challenge in application. It is also important to define which performance dimensions (costs/productivity, quality, time) are to be significantly improved.

As there are usually only limited resources available for optimization, not all dimensions can be optimized at the same time. In addition, the performance dimensions are in conflict with each other from a certain degree of optimization. This is known as the magic triangle. It is therefore important to define exactly what is to be achieved and which tool is suitable for this in the laboratory.

For example, a spaghetti analysis is suitable for analyzing the routes in the laboratory ( productivity performance dimension), while an Ishikawa diagram can be used to narrow down and identify possible causes of errors ( quality performance dimension).

Background

E-learning: Online course

The term “lean lab” (short for “lean laboratory”) has become established for the application of lean management in the laboratory. Lean can be applied to many different areas in the laboratory: For example, to test processes but also support activities, such as materials purchasing, laboratory planning or the design of the laboratory layout(lean lab design). In recent years, lean has also been increasingly applied in the administrative area (lean admin) and for management activities(lean leadership).

There are a few special features to consider for laboratories: First of all, laboratory staff usually have scientific skills but rarely have extensive prior business knowledge. It is therefore important to introduce the participants to the lean topic slowly and to explain technical terms well. In addition, lean techniques must be adapted to the specifics of laboratories. For example, it is often necessary to classify observations and interpret results in a laboratory-specific context. Only then can the optimization possibilities be fully recognized and suitable solutions developed.