Our laboratory benchmarking

Our laboratory expertise covers the entire spectrum of laboratory management challenges. From day-to-day operations to organizational and strategic issues.

We offer both consulting and training on all the topics presented. We have also developed laboratory-specific online courses for many of the topics.

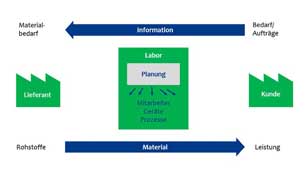

Lean in the lab

Lean management refers to a series of methods, procedures and principles for the efficient organization of the entire value chain. Many laboratories have applied lean over the last two decades and have increased their productivity, reduced throughput times and increased the reliability of processes. Lean has thus become a proven and indispensable component of successful laboratory management.

Lean laboratory processes

The execution of tests can be fundamentally optimized using lean techniques. This can improve employee productivity by up to 50% and reduce errors.

Lean Lab Design

Lean device layout

Lean documentation

Lean Lab Supply

Lean Leadership

Lean management in the laboratory - introduction

Waste analysis

Route analysis

Value stream mapping

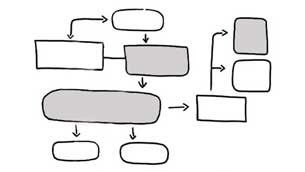

Process mapping

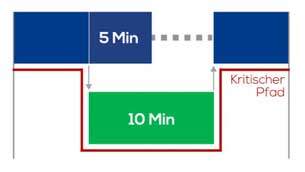

Critical path analysis

Swimlane diagram

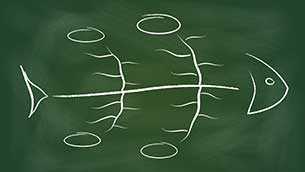

Ishikawa diagram and 5 Why method

Root cause analysis

Overall Equipment Efficiency (OEE)

5S in the lab

Kanban, pull and milk run

Poka Yoke

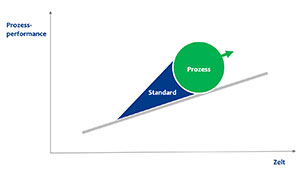

Standard processes

Selection of optimal storage locations

Determine optimum device layout

Visual Management

Gemba

Laboratory new construction and conversion

Planning the renovation, conversion or new construction of a laboratory is a complex and exciting task. For many managers, it represents a unique challenge in their professional lives. In addition, the design of a laboratory layout requires the involvement of laboratory technicians and intensive coordination with many partners: architects, laboratory planners, structural engineers and laboratory furniture and equipment manufacturers. With the right approach, the planning effort can be reduced and the efficiency of processes and employee satisfaction increased.

Lean Lab Construction

The execution of tests can be fundamentally optimized using lean techniques. This can improve employee productivity by up to 50% and reduce errors.

Lean Lab Design

Optimize land use

Lean Lab Supply

Laboratory management

The demands placed on laboratory managers have increased in recent years. In addition, the range of tasks has become more diverse: a constantly changing regulatory environment, increased expectations of “good management” of employees, effective control through the use of key figures and, last but not least, the need to increase quality, costs and time through lean management techniques. In order to meet these expectations, it is more important than ever for managers to continuously expand their knowledge and apply it in everyday laboratory work.

Financial analysis of laboratories

Laboratory organization

Laboratory strategy

Laboratory outsourcing

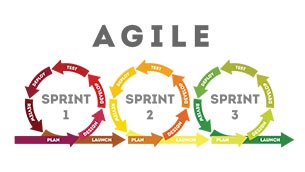

Lead time & agility

In a world of ever shorter response times and regular changes, it is important to react quickly and adequately to changes. But regardless of this, it is also important for laboratories to continuously reduce the throughput time of tests and projects.

Optimization of throughput time

Agile Labs

Planning for efficiency & speed